Aluminum Pipes in Marine Applications: Durability and Performance

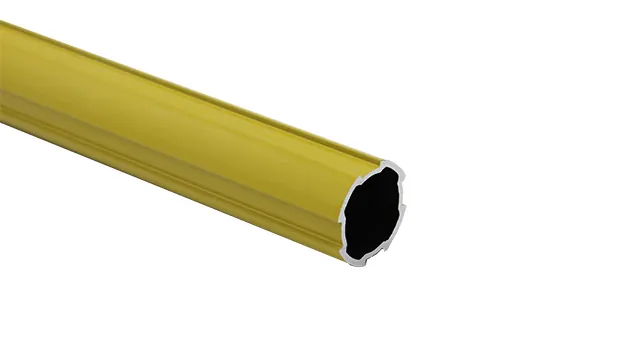

Aluminum pipes, with their lightweight nature, make installation and maintenance easier, reducing the burden on marine structures. Unlike steel, which can expand and contract significantly with temperature changes, aluminum maintains its shape, reducing wear and tear. This stability is crucial, especially in environments where constant stress and varying temperatures are the norm.

Moreover, aluminum's corrosion resistance is a standout feature, making it ideal for marine settings. The passive oxide layer on aluminum pipes resists corrosion effectively, ensuring that structures remain robust in salty and humid environments. This is particularly important for ship hulls, offshore platforms, and other marine facilities that are frequently exposed to saltwater.

Another key advantage is the flexibility of aluminum pipes. They can conform to various structures without buckling, making them suitable for tight spaces and irregular configurations. This flexibility is essential in marine applications where space constraints are common, ensuring that pipes can be installed efficiently and effectively.

Advantages of Using Aluminum Pipes in Marine Applications

The advantages of aluminum pipes extend far beyond their physical properties. Weight reduction is a significant benefit, enhancing the efficiency and fuel economy of marine vehicles. By reducing the overall weight of a vessel, aluminum pipes help improve its handling and performance, making it easier to navigate through rough seas.

Furthermore, the eco-friendliness of aluminum pipes aligns with global sustainability goals. Aluminum has a lower carbon footprint compared to steel or copper, making it a preferred choice for environmentally conscious projects. The versatility of aluminum pipes allows them to be used in a wide range of applications, from shipbuilding to pipeline installations, ensuring they can meet the diverse needs of the marine industry.

Real-World Applications of Aluminum Pipes in Marine Settings

Aluminum pipes are integral to numerous marine applications, highlighting their reliability and performance. In marine vehicles, they are used to support structures and improve safety. For example, aluminum pipes are employed in stabilizing systems on cruise ships, ensuring that these structures remain stable during rough seas and high winds.

Offshore wind farms are another significant area where aluminum pipes play a crucial role. They are part of the support structures, ensuring stability under constant pressure from wind loads. The use of aluminum pipes in these applications helps reduce the overall weight of the structures, enhancing their efficiency and durability.

Aluminum pipes are also used in corrosion inhibitors and energy storage systems. In coastal areas, these systems are critical for protecting assets from corrosion and ensuring the reliable operation of energy storage facilities. By providing a durable and efficient solution, aluminum pipes contribute to the overall safety and efficiency of marine operations.

Challenges and Considerations in Using Aluminum Pipes

Despite their numerous advantages, aluminum pipes face several challenges in marine environments. Extreme temperatures and corrosive fluids require specialized coatings and treatments to protect the pipes from damage. Specialized coatings can enhance the corrosion resistance of aluminum pipes in highly saline environments, ensuring they remain robust under harsh conditions.

Maintenance is also a critical consideration, as regular inspection and repair are necessary to address wear and tear and ensure optimal performance. Different alloys are used to address varying environmental conditions. Some alloys offer higher strength, making them suitable for high-pressure applications, while others provide better corrosion resistance, ensuring that the pipes can withstand the harsh marine environment over long periods.

Future Trends and Innovations in Aluminum Pipe Technology

The future of aluminum pipes in marine applications looks promising, with ongoing innovations enhancing their performance and sustainability. New alloys are being developed to improve strength and resistance, ensuring that aluminum pipes can withstand even the harshest conditions. Additive manufacturing is revolutionizing the production of aluminum pipes, enabling the creation of complex shapes and customized solutions that were previously impossible.

Smart technologies are also being integrated into aluminum pipes, providing real-time monitoring and data collection. This allows for better understanding of the pipes' performance and conditions, enabling proactive maintenance and increased reliability. These advancements not only enhance the durability and performance of aluminum pipes but also align with the increasing demand for sustainable and efficient materials in the marine industry.

The Future is Bright for Aluminum Pipes in Marine Applications

Aluminum pipes are an indispensable part of marine applications, offering durability, efficiency, and sustainability. Their unique properties and versatile nature make them a preferred choice for engineers and decision-makers facing the challenges of marine environments. By adopting aluminum pipes, projects can ensure longevity, efficiency, and environmental stewardship.

aluminum pipes are the unsung heroes of marine engineering, delivering unparalleled performance and reliability. Their lightweight nature, corrosion resistance, and flexibility make them an essential component in marine structures. As the marine industry continues to evolve, the use of aluminum pipes is likely to become even more widespread, driven by innovations in alloys, manufacturing techniques, and smart technologies.

Contact person: Kalisa

400: +86 400-8055-828

Tel: +86-755-29554900

Mobile phone: +86 15919917235

E-mail: service@szsunqit.com

Add: Block3# HongTianFu Industry Park GuanGuang RD. Dashuikeng Community FuCheng Street LongHua District Shenzhen China.